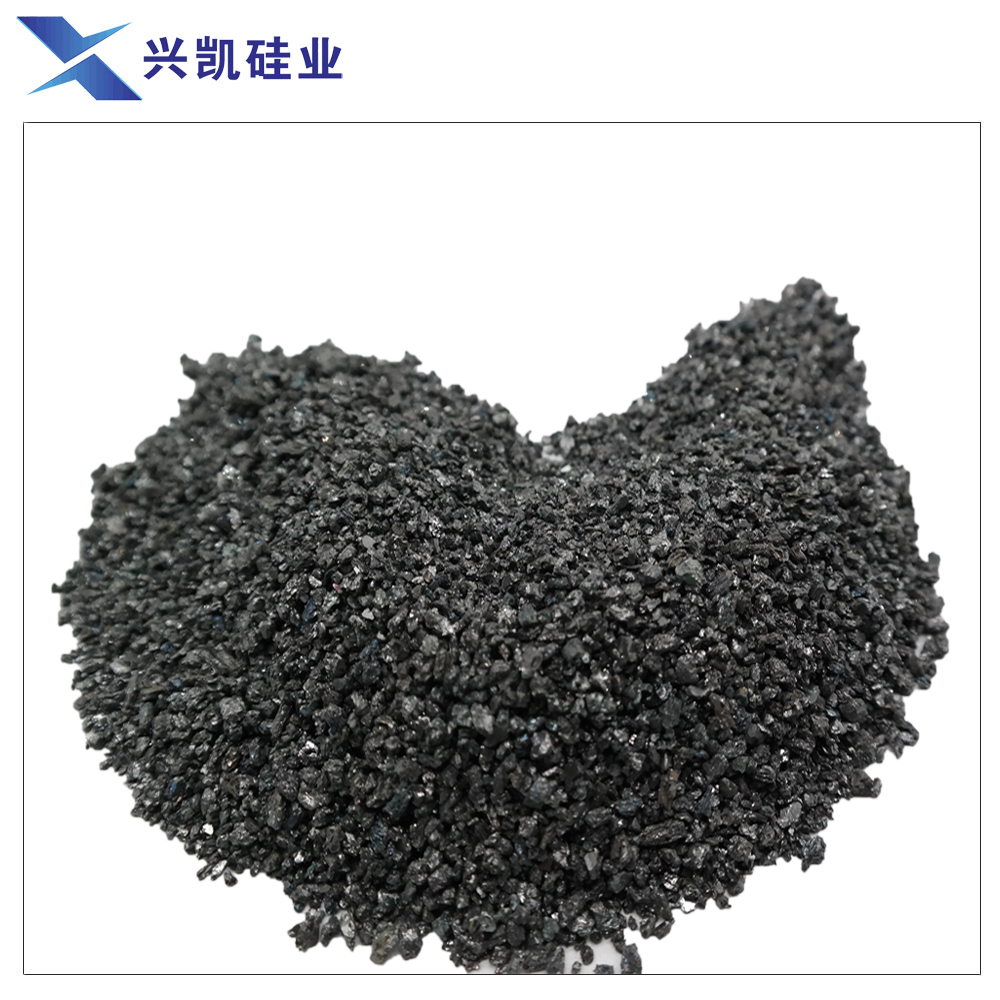

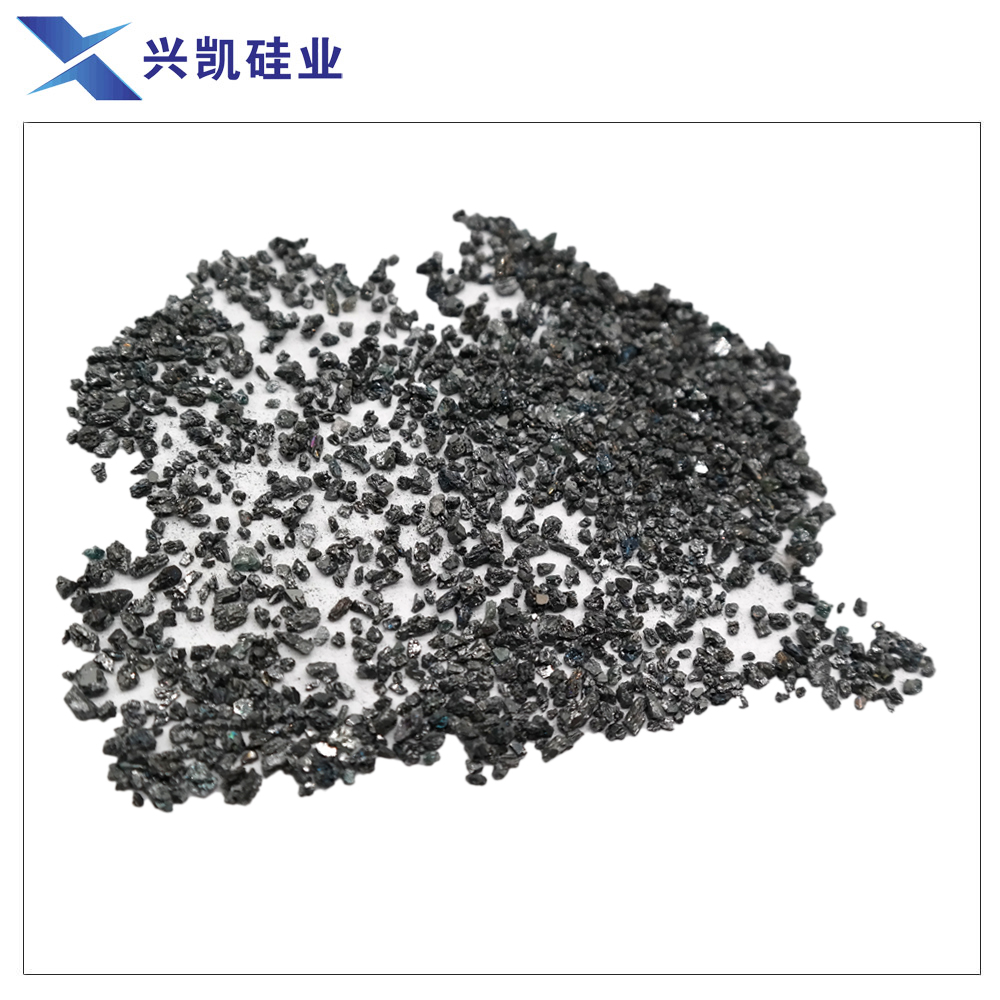

Black silicon carbide in abrasive refractory

Basic Info

Model No.: silicon carbide98%

Product Description

Product Introduction

Black silicon carbide in abrasive refractory, it has high purity, hardness characteristics. Black silicon carbide mainly used in abrasive, refractory and electronic industries.

The silicon carbide used as a heating element, a non-linear resistance element and a high semiconductor material. Heating elements such as silicon carbide rods, non-linear resistance components and different kinds of lightning protection valves. Different size and packaging can be processed according to customer`s requirements.

Application

1. Electrical purposes --- The silicon carbide as a heating element, a non-linear resistance element and a high semiconductor material. Heating elements such as silicon carbide rods (for 1100 ~ 1500 ℃ work a variety of electric furnace), non-linear resistance components, different kinds of lightning protection valve.

2. Chemical application--- because silicon carbide can be dissolved in molten steel and molten steel with oxygen, metal oxides will react to generate carbon monoxide and silicon-bearing slag. So it can be used as smelting steel purification agent, that is used as steel deoxidizer and cast iron tissue modifier. This generally uses low purity silicon carbide to reduce costs. At the same time as the raw material for the manufacture of silicon tetrachloride.

3.Refractory materials and corrosion-resistant materials --- mainly because of silicon carbide with high melting point (decomposition), chemical inertness and thermal shock resistance, so silicon carbide can be used for abrasive, ceramic products fired furnace with shed and sagger, Zinc Industry vertical cylinder distillation furnace with silicon carbide tiles, aluminum electrolysis cell lining, crucibles, small pieces of furnace and other silicon carbide ceramic products.

4. Abrasive - The silicon carbide with high hardness, chemical stability and toughness characteristics, so silicon carbide mainly used to manufacture bonded abrasive, coated abrasive and free grinding. Using this raw materials to process the glass, ceramics, stone, Cast iron and some non-ferrous metals, hard alloys, titanium, high-speed steel cutting tools and grinding wheels.

Transportation and package

1. Transportation and handling: During the transportation process, the silicon carbide shall not be dragged with hook, should prevent mixing with hard materials. It should be light unloading to reduce packaging crushing.

2. Storage: The silicon carbide should be stored in a cool and dry place, to prevent rupture of bags, to prevent moisture and other substances to affect the product. Storage should away from sources of pollution.

3. Non-flooding: The silicon carbide is high abrasive, so in the transportation, storage and the process, we must absolutely prevent flooding to insure the quantity of the products.

Product Categories : Silicon Carbide > Silicon Carbide Sand